Industry Leading

Powder Coating Services

What is powder coating?

A type of finishing process whereby a powdered, free-flowing dry powder is applied to a surface with either the use of an electronic charge and spray gun or pre-heated dipping to provide an architecturally durable and enhanced surface. Powder coating requires extensive surface preparation including blasting and cleaning to ensure surfaces are ready to be treated, otherwise, coatings will not stick to the surface correctly.

- Durable

- Environmentally friendly

- Time and cost-effective

- Polished finish

Powder coating is one of the most popular methods to paint items, parts and other surfaces. It yields many advantages over other painting and coating applications – from its durable yet attractive finish to its environmental advantage and efficient cost.

The powder coating process

Powder coating offers surface reinforcement and strengthening through a multi-phase finishing process suitable for metal items. The exact process used and finish produced during powder coating differs according to the medium chosen and surface treated, however, all approaches include three basic steps: surface preparation, powder coating and curing.

Surface preparation

Completing surface preparation before any media is applied is key to a successful and uniform finish; contaminants or debris remaining on the surface will interrupt its adherence and end with a poor result. We ensure that each element of this process is performed to the highest possible standard, guaranteeing an immaculate canvas for powder coating.

An abrasive blasting method appropriate for the surface is selected in order to suitably strip away any corrosion, old paint and coatings and dirt. Other preparation services can include etching to create a rough surface, allowing for the coatings to sink in and fix to the substrate as best as possible.

Powder coating procedure

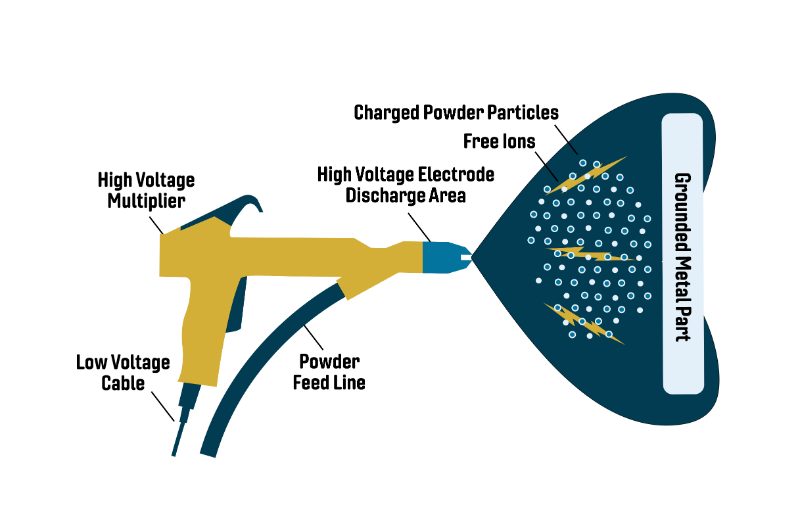

There are two types of powder coating processes; Electrostatic Discharge (ESD) and Fluidised Bed powder coating.

ESD uses electronically charged particles through a specialised spray gun to coat metal surfaces. A magnetic force draws the powder to the surface, minimising wasted materials and reducing clean-up time. Fluidised bed powder coating uses a compartment of thermoplastic powder that moves like a liquid; as parts are pre-heated before being dipped into the bed, powder bonds with the surface in even the smallest ‘nooks and crannies’.

Heat curing

The overall curing process turns the molecular structure of the powder into a very resistant, yet flexible, protective and decorative coating.

Curing, for both ESD and fluidised bed, consists of heating elements after powder coating application to between 162 – 232°C for 10 minutes to over an hour depending on the size of the surface. Whilst the parts are heated, a process referred to as ‘flow out’ sees the powder transform into a liquid and is a vital part of the materials fusing together. A rule of thumb is to cure for 20 minutes after flow out has taken place to secure the coating correctly.

A Powder Coating Company You Can Trust

When you choose AS Blasting and Coatings for your resurfacing needs, you are guaranteed complete customer satisfaction. We know that trust is vital to a successful experience, so rest assured that all AS employees are CSCS Registered and carry all relevant certifications.

Our latest Powder Coating projects

Our adherence to the highest industry standards and delivery of the utmost workmanship ensures each of our clients receives the quality results they deserve. We truly believe that our experience and knowledge within this complex industry is your best solution – but don’t just take our word for it – see for yourself what our abrasive blast cleaning services can do for you!

Get a free quote today

Request a Callback

Fantastic service from Mat. He went above and beyond to accommodate me and I had the parts back within a few days. All work was finished to a high quality. Very very pleased with the end result and the service as a whole. Would recommend.

Great service provided by a great team at AS Blasting & Coatings. Highly recommend it to anyone out there looking for blasting and coating services. this is the company you need to use so get in contact with them.

Powder Coating FAQs

What does a powder coating do?

Applied in powder form, this coating seamlessly covers the surface, cured in an oven reaching over 400°C to set and bond the powder coating to the substrate. A powder coating can provide a thin layer of protection against weathering, rust, and corrosion whilst offering a fresh finish and/or colour. It can be applied for industrial protection or a domestic item refresh, both will perform and protect the surface it’s applied to, acting as a barrier between the contaminant and substrate.

Is powder coating better than paint?

The molecular structure of powder coating allows for a more even and complete application as opposed to a liquid paint coating; avoiding any paint build-up from sagging or dripping. Powder coating, although lightweight, is incredibly durable once cured at high temperatures. In comparison to paint, overspray is limited as powder coating particles are electrically charged and are drawn to the metal surface. Paint sprayed that does not hit the intended surface will be lost and unable to be used, whereas powder can be scooped up and recycled for another application.

In terms of environmental and technician safety, paint is the more harmful option out of the two; VOCs are absent in powder coating as the active product - polymer powder - is dormant. Paint spraying sends toxins into the atmosphere when in use and waste contributes to landfills.

How long will powder coating last?

Powder coating is applied to give a decorative and protective layer on industrial machinery as well as domestic things in your homes. Items that are used regularly or are in demanding environments need long-lasting coatings that won't fail under pressure; with specialised Electrostatic Discharge or Fluidised Bed powder coating application techniques you get just that. A well-applied powder coating with a solid bond with the substrate will last up to 20 years, giving durable protection from scrapes, knocks, and scratches to weathering, rust, and corrosion.

Does powder coating hide imperfections?

When applied, powder coating is drawn to all areas of the intended surface ensuring the coating is opaque which will hide any discolouration or facade imperfections. It can cover and fill in minor scratches and dents, however, a good end result will only be achieved with correct preparation and thorough workmanship. Prior to application, blast cleaning will remove any dirt, grease, and pollutants that may affect the coating’s adherence to the surface. Abrasive blasting will also help to smoothen and even out the substrate to guarantee parts are in the best condition possible before powder coating begins.

What metals cannot be powder coated?

The procedures metals go through to be powder coated are extensive and some materials cannot handle the abrasive blasting or the intense curing heat. Automotive parts that are constructed of or contain resin and plastics cannot be electrically charged, therefore powders will not be attracted or stick to the surface. These components’ molecular structure will also not be able to withstand the 400°C curing stage of the powder coating process, as bubbles will form or warping will occur. With that being said, all metals that are not connected or contain non-conductive materials and can hold an electrostatic charge can be powder coated.

How does powder coating work?

Metal surfaces can be coated with either an electrically charged or fluidised bed powder for protection and to sustain durability and performance. Metal is put through blast cleaning methods, appropriately chosen depending on its condition. Once it has been sufficiently prepared, powder coating is applied and cured.

With the use of ESD, Electrostatic Discharge, the metal surface is electrically charged to draw the powder towards it and molecularly bond, creating a tough exterior. This method ensures the entire surface is coated evenly whilst reducing wasted materials.

Once this initial process has been completed, the metal surface will have a new, hardened layer which provides colour enhancement, an uniform appearance and a barrier against scrapes, chips and damage when performing. It can be utilised for industrial appliances and machinery but also applied to domestic items such as bike frames and garden furniture.

We don’t just offer Powder Coatings

We accommodate an eclectic range of blasting and coating projects throughout East Anglia, the South East and the East Midlands. Ensuring the best results are always achieved, we provide a bespoke approach, tailored to the surface’s needs using our wide range of services.

Protective Coating

For surfaces consistently exposed to harsh weather conditions or high temperatures, a coating of protective, resistant liquid metal substances can be the key to avoiding corrosion and ensuring long-term durability. Other benefits of this service include increased conductivity, enhanced friction properties and improved decorative finishes.

Blast Cleaning

Many of our blasting services, such as those for brick or stonework, can be performed at the site of the surface for convenience, whilst many smaller components, such as oak beams and motorbikes can be blasted at our dedicated in-house facility. We use a variety of abrasives to achieve the specific finish required, including Australian garnet, copper slag, aluminium oxide, stone grit, recycled glass and glass bead.